BACK

BACK

4 Ways to Deal with 4CP

4CP may be the only acronym more feared by large Texas energy users and industrial operations than the IRS.

Across almost all of Texas, operators are subject to an unpredictable fee for using electricity during peak times. Unlike normal peak periods, 4CP days are notoriously difficult to predict – and they have implications for many months to come.

The 4CP concept is simple

When an industrial operation uses electricity, it doesn’t pay a flat rate. It pays very different prices based on when it’s operating. This price variation reflects real-time conditions on the grid. In a free market (which Texas is, of course), high demand or low supply means high prices.

This can take several forms. This article focuses on Coincident Peak – or as it’s known in Texas, 4CP. From June through September, utilities measure each site’s usage during the hottest few minutes of each month. It then uses those readings to calculate a separate fee every month of the following year.

The concept is simple: reduce peak load on the grid. That helps avoid blackouts, which is worth big money.

The reality of dealing with 4CP is complex

You may have noticed a problem: nobody knows when the hottest period of the month will be (or more precisely, the highest-demand period on the grid). That leaves a few options:

- Write off 4CP charges as a cost of doing business

- Guess when the peaks will occur and reduce demand preemptively

- Use analytics for better insights and reduce demand only as appropriate

- Create rules that shut down equipment whenever prices go above a certain threshold

How to decide?

The first option is easy but costly. Many companies still operate this way, but doing nothing is becoming an untenable strategy. This is true for 4CP and for demand management in general, especially as grid emergencies become increasingly common.

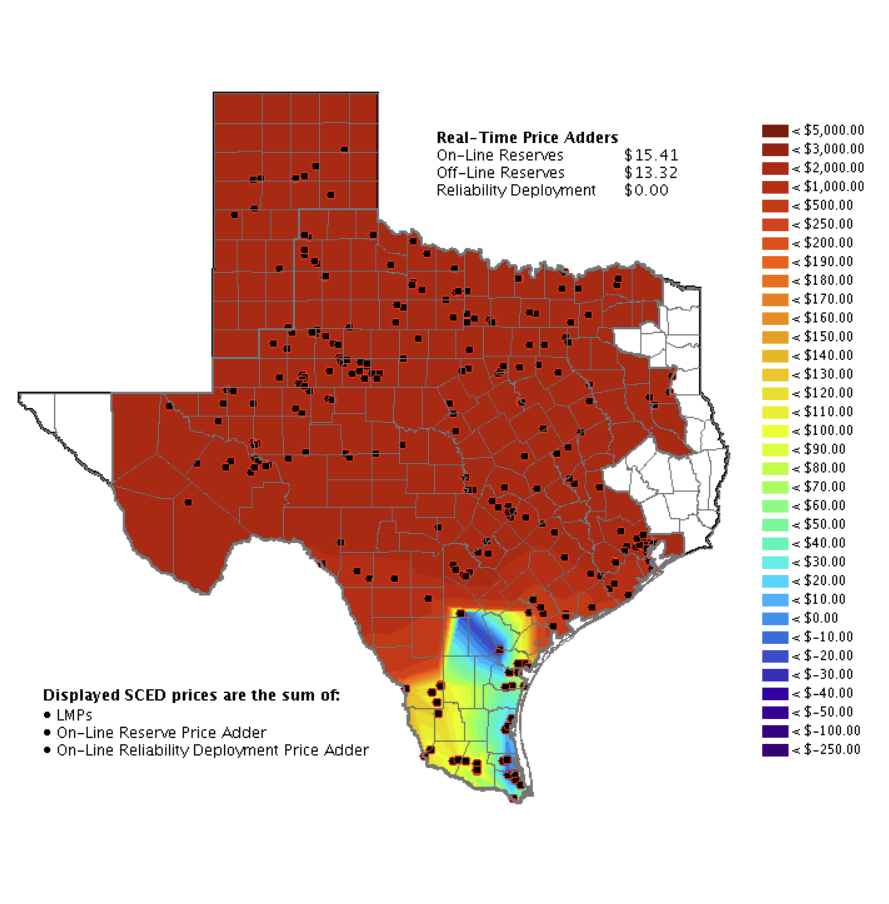

The second option requires a little more vigilance. Readily available data from ERCOT, the Texas grid operator, shows real-time grid conditions which can signal a coming peak. Operators can then choose to shut down or shift demand – but this is error-prone, and it comes with a significant opportunity cost.

Smart Coincident Peak and 4CP Management

The third option is sometimes described as Smart Coincident Peak Management. Four big innovations have driven the growth in this space:

- Earlier peak predictions

- Historical load and intelligent analytics

- Customized alerts

- Load control automation

Using modern analytics tools, the likelihood of a Coincident Peak event can now be seen days in advance, rather than hours. Software that helps users visualize this likelihood can also help teams prepare ahead of time to allow for safe curtailment of large equipment.

It can also help to understand exactly how much energy a site uses and when. Good historical data gives teams the confidence to shed larger loads when the time comes. For example, if you know you can turn off a certain water pump for 3 hours before the tank fills up, you may decide to flip that big switch during a peak event, rather than just lights and HVAC.

Perhaps the most useful form of analysis is to not only predict grid peaks, but also compare expected 4CP charges to the opportunity cost of stopping production. This is now possible through platforms that connect energy and production data in a normalized way.

Perhaps the most useful form of analysis is to not only predict grid peaks, but also compare expected 4CP charges to the opportunity cost of stopping production.

It’s also now possible to set alert thresholds tailored to the individual risk tolerance and revenue expectations of each site. This helps reduce “alert fatigue,” which can be a major source of frustration for people playing this game.

Finally, once teams know what to expect, they have to do something about it. Automation can help fill the gap between software and circuit breaker. It’s now possible to automate load shedding sequences, meaning qualified operators don’t have to be on site. In some cases, it all happens with a simple text message approval.

Real-time rate avoidance

A separate but related practice is to create custom rules for shutting down various processes given certain price signals from the grid. This approach does not attempt to predict grid peaks at all, but the effect is largely the same.

For instance, if real-time grid prices go above $150/MWh, operators may choose to shut off one pump. At $200/MWh, they may shut off another. At some point, depending on the operation, a full shut-down might make sense. These thresholds can be adjusted day-by-day based on various parameters.

This does nothing, inherently, to predict and respond to Coincident Peak signals. However, since grid prices tend to be high during these periods, it’s very likely that the operation will already be curtailed when the peak occurs.

This strategy also has the added benefit of creating substantial savings year-round, even outside the peak months. Many operations can save tens of thousands of dollars a month or more, with minimal effort. Of course, it also requires a high level of load flexibility.

Automation is possible here as well. Once the rules are set, operators can either curtail manually, or they can integrate control systems and PLCs with software to create a seamless rate avoidance program.

One size doesn’t fit all, but some methods are better than others

There are many strategies for managing Coincident Peak charges, including some not mentioned above. The right approach will be different for every company.

That said, there are clear benefits to taking a smart approach to Coincident Peak management. With modern tools, companies can save time, save money, and reduce emissions all at once. They also help keep the grid stable for everyone else.

Another often-overlooked benefit of a modern system is simply recordkeeping. Software tools that provide easy access to historical data can be useful for proving compliance in the case of billing discrepancies, for example.

Regardless of the approach to managing 4CP charges, one thing is clear: doing nothing is an increasingly costly strategy. As in any industry, software and automation are beginning to change the way people think about Coincident Peak.