Benefits & Value

Continual innovation through industry 4.0

Industrial businesses face huge pressure to innovate, seek efficiencies, adapt to changing needs, and improve the bottom line. The aim of the Industry 4.0 revolution is to enable businesses to take a holistic view of the whole business to identify areas ripe for optimization. To achieve this, you have to gather data from all parts of your business and analyze and evaluate the data in order to make informed decisions that will help businesses become more efficient, produce higher-quality products, and improve overall ROI.

Benefits & Value

Continual innovation through industry 4.0

Industrial businesses face huge pressure to innovate, seek efficiencies, adapt to changing needs, and improve the bottom line. The aim of the Industry 4.0 revolution is to enable businesses to take a holistic view of the whole business to identify areas ripe for optimization. To achieve this, you have to gather data from all parts of your business and analyze and evaluate the data in order to make informed decisions that will help businesses become more efficient, produce higher-quality products, and improve overall ROI.

The data challenge

Unfortunately, what appears easy in theory is extremely complex in reality. Not only do you have vast amounts of data, but information is coming from diverse sources, each with its own unique parameters. To add complexity, data may be location-specific, in a unique format, or measured in different units. All of these make it seem virtually impossible to normalize and analyze data in its raw output form, or compare it with disparate and diverse data from multiple systems across different sites. Leveraging the data to optimize key aspects of your business feels far-fetched.

The complexities of data and the need for a robust solution

That’s where we come in. Innovation requires experimentation and iterations, which can be expensive and are often not scalable. Ndustrial gives companies more opportunities for successful digital transformations.

Whether you have focused energy optimization requirements or big data challenges, we can help your business digitally transform through meaningful, real-time data analytics and powerful insights that evoke immediate action and deliver on the promise of Industry 4.0.

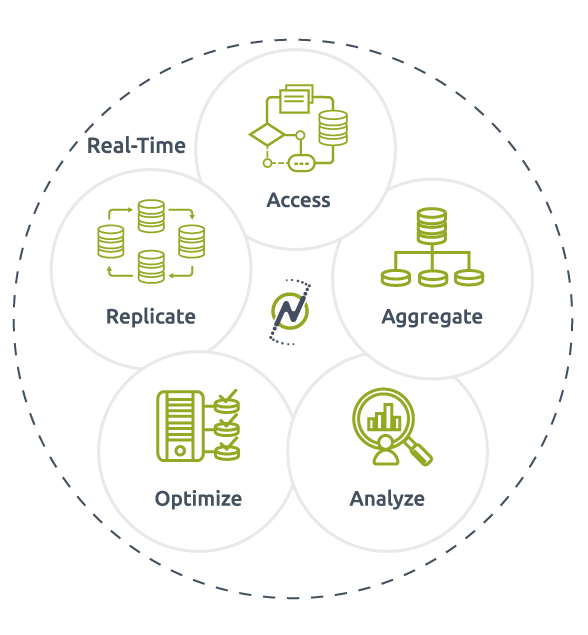

A comprehensive approach to real-time optimization

Access: Gather digitized data from disparate sources

Aggregate: Normalize data to common data sets

Analyze: Extensively examine deep data analytics, beyond just KPIs

Optimize: Leverage insights to change parameters that can impact performance and revenue

Replicate: Our data scientists can utilize the algorithms and insights to help replicate and scale beyond just a single-use

All of this is done in real-time, with critical data available within seconds.

Flexible intelligence platform

We offer both customized and off-the-shelf software solutions to help industrial facilities optimize their digital data and achieve true energy intelligence. We realize each factory is distinct and may require a solution that’s customized for their needs, so our data scientists and service experts work closely with you as your master solution architects. We’ll optimize every aspect of our real-time industrial intelligence platform to meet your specific challenges. We partner with our customers to create very specific implementations and algorithms tailored to deliver highly optimized results.

Deep analytics beyond the KPI

While some companies can successfully aggregate and equate the data, they fail to leverage the true meaning of the data and make an impact on the output of the operation. Gathering data to determine a KPI is only the first step. But a KPI alone is not going to convey HOW to make changes to improve operations. What’s important – and extremely difficult to achieve – is leveraging the insights learned to actually optimize operations and impact the bottom line.

“It’s so much more than delivering KPI data or measuring performance. We don’t just help a company track and report their yield, we give them tools to determine how to get an even better yield with lower raw material costs. We help change the parameters and thinking based on insights we’ve learned. That’s the kind of impact our solution has on business.”

– Jason Massey, CEO of Ndustrial

Predictive modeling enabling continuous Optimization

The key to optimizing efficiencies and truly impacting operations is the ability to create autonomous algorithms to enable sustainable and scalable models. These can be used to test different scenarios, allowing continuous operational optimization. While AI, machine learning and digital twin technologies have come a long way in industrial optimization, they still require human intervention, and new data training is required with even the slightest change in operations, raw material, other factory-related process. These are great one-off technologies, but they lack the true scalability and are not replicable across factories or even across lines within a factory.

“While AI and digital twin technology continually evolve and improve performance for specific use cases, they currently cannot adapt quick enough to become truly scalable. Building a digital twin is not enough — it is critical to anchor that effort with purpose and intent so that actions are meaningful and replicable.”

– John Crawford, CTO of Ndustrial