BACK

BACK

Tire Recycler Saves Hundreds of Thousands in Energy Costs in Less Than 4 Months

Genan dodges energy inflation with automated load control

“I’ve saved hundreds of thousands, making it possible for me to produce in a very volatile energy market.”

– Michael Agerkilde, Genan COO

At Genan, payback is measured in months, not years.

It sounds too good to be true.

Most IoT projects fail, and those that do succeed often fail to reach their full potential. So how did Genan, the world’s largest mechanical tire recycler, break the mold?

By focusing on a simple, lucrative opportunity: saving energy costs through real-time demand management. Too many projects doom themselves to “scope creep” by taking on a major digital transformation. Genan stayed focused on a single goal: dodging electricity price spikes.

They then automated their response to electricity prices so they no longer had to rely solely on operator discretion. This automation has proven remarkably successful at avoiding price spikes, adding hundreds of thousands of dollars to their bottom line in a matter of months.

Real-Time Pricing

Industrial facilities don’t get charged a flat rate for electricity the way households do. Depending on the contract, industrial rates may vary by season, by day, and even by hour. At Genan’s Houston plant, rates actually change every 15 minutes. This creates huge challenges — and huge opportunities.

The challenge, of course, is that price volatility can mean significant swings in profitability for energy-intensive operations. Although Genan’s electricity prices are lower in the US than they are in Europe, the volatility is much higher. Prices at the Houston plant can easily spike by a factor of 100 during extreme events.

During the 2021 Texas freeze, many businesses got hit with massive bills due to skyrocketing real-time prices from the grid. Genan was no exception. Having received notification of the impending event late on a Friday, they failed to curtail right away and were charged hundreds of thousands of dollars for electricity that weekend.

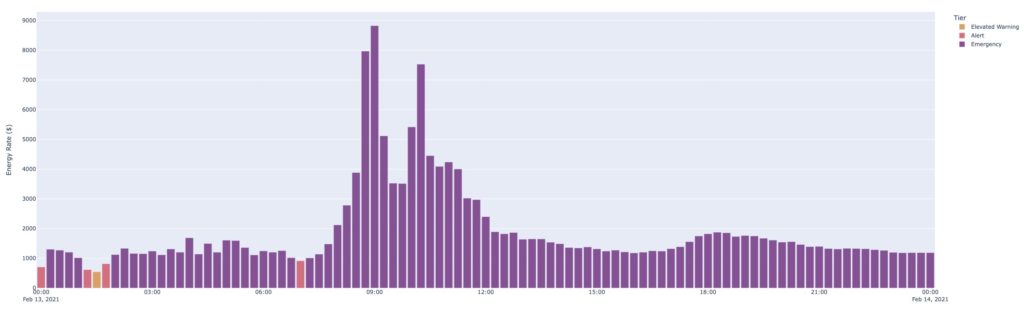

Had they curtailed appropriately, they could have avoided nearly $3 million in energy costs during the week of the storm. Baseline electricity rates are roughly $30 dollars per megawatt-hour ($30/MWh). For many hours that week, spot prices hovered around $9,000/MWh – a 30,000% increase. Regardless of foregone revenue, avoiding rates like these would have made obvious sense.

Houston spot prices during Winter Storm Uri (February, 2021)

ERCOT spot prices soared roughly 300x compared to baseline rates on February 13, 2021. Had Genan curtailed appropriately, they could have avoided nearly $3 million in electricity costs during the week of Winter Storm Uri. Note that normal prices would be indicated in green and yellow, so even the baseline in this chart is extremely elevated.

That’s when Genan doubled down on demand management. From that point forward, they responded to every electricity price above a certain threshold.

When you’re risking everything with spot prices, you need a warning system, and ideally an automated system, that will shift your load as prices go up.

– Michael Agerkilde, Genan COO

Embracing the Challenge

Genan had signed up for real-time pricing with its electric provider, believing the business could save money by shifting production toward the cheapest hours. It’s not as difficult as it may sound. Most of the time, electricity is cheap. Certain periods are more taxing to the grid, and a few extreme events can cause wild spikes in the utility’s costs. Avoiding these spikes allows customers to save a great deal of money.

That’s because when utilities charge a flat rate, they’re averaging out their costs. Those costs are driven not just by energy delivered, but by the capacity they must build to handle a worst-case scenario. That spare capacity costs a lot of money. By shutting down during the costliest periods, Genan saves the grid operator disproportionate amounts of money — and with real-time pricing, they get to share in those savings.

For Genan, participating in real-time pricing is a no-brainer. “I would never do anything else,” Agerkilde explains. To reliably avoid peak periods with only 15 minutes’ notice, though, Genan realized they could no longer rely on operator discretion alone. They needed to automate the process.

To integrate with plant floor equipment, Ndustrial installed a system that receives real-time rate signals from the grid operator and compares those to daily curtailment thresholds for each part of Genan’s process. An IoT edge device can then send a request to shut down equipment accordingly. All this is based on an open software platform that integrates multiple data sources into a common and extensible framework.

Staggering Results

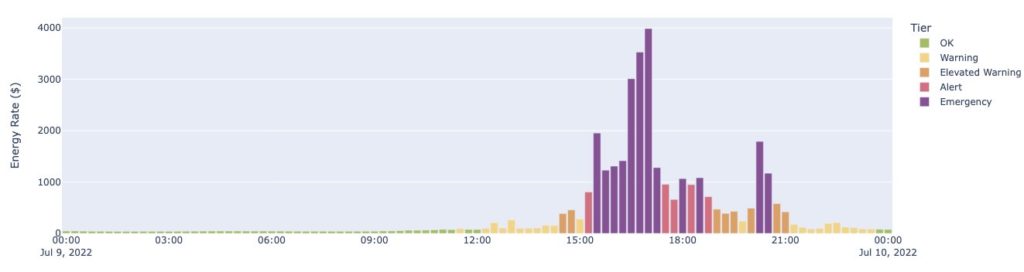

It can be hard to comprehend just how much of a difference this approach can make, so let’s consider another real scenario. On the afternoon of July 9, 2022, the spot price surpassed $4,000/MWh. By automatically curtailing certain processes above $120-$150/MWh and shutting down the entire facility above $350/MWh, Genan avoided over $20,000 in energy spend on that afternoon alone.

Houston spot prices on a hot summer afternoon (July, 2022)

ERCOT spot prices occasionally spike 100x during hot summer afternoons, as was the case in July 2022. Summer price spikes such as this may also coincide with 4CP days in Texas, in which case curtailing load during these events would also mean substantial year-round savings.

In total, Genan avoided hundreds of thousands of dollars in energy costs in its first few months using automated load control — paying back their investment almost immediately. Future efforts will layer demand response onto the solution architecture, allowing Genan to not only save money but also earn revenue for their demand management program. All this will help Genan to not only turn spent tires into valuable feedstocks, but to do it in the most responsible way possible.

Because peak periods on the grid are also the dirtiest, simply shifting demand away from high-traffic times can have outsized impacts on carbon emissions. These efforts also help keep the grid stable for other users, and they can even help grid operators incorporate more renewable energy by providing flexibility to offset periods of low solar and wind production.

In today’s divided world, it can be hard to believe that win-win solutions still exist. Genan is proof that they can be found.

Learn more about Ndustrial’s load control capabilities here.