BACK

BACK

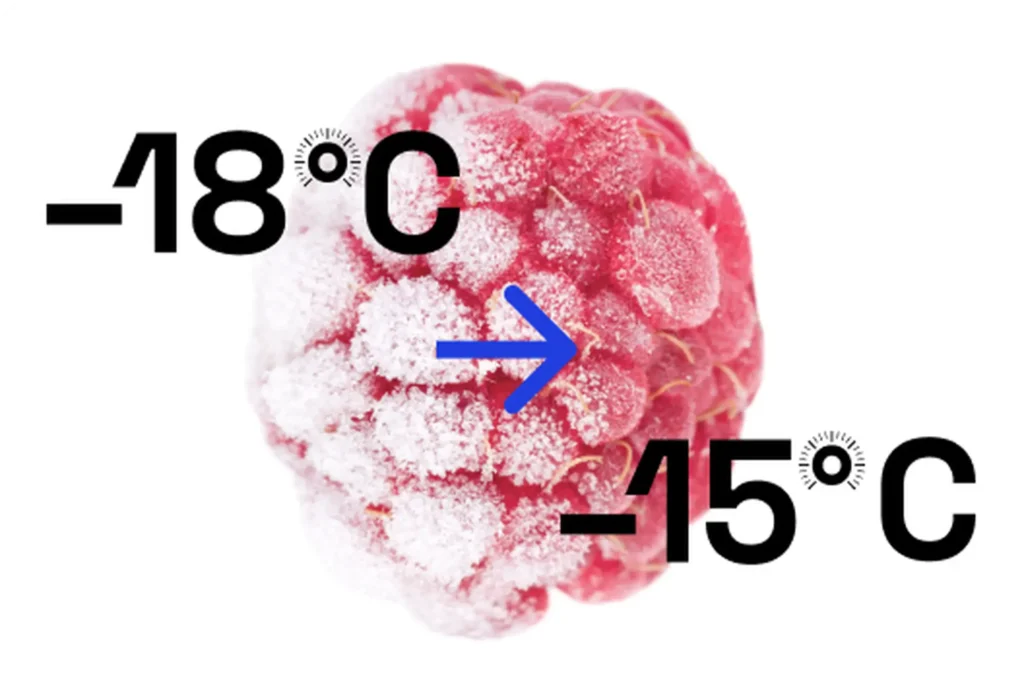

The Move to Minus 15 Celsius

The Move to -15°C is a powerful coalition driving efficiency in the global frozen food supply chain

The cold supply chain is entering a transformative era. A global coalition of food and beverage manufacturers, cold storage leaders, logistics providers, and sustainability advocates have come together under a powerful new banner: The Move to Minus 15 (degrees Celsius).

The Move to Minus 15 is a growing coalition seeking to update frozen food temperatures to drive efficiency across the cold supply chain. Championed by organizations like Maersk, Lineage, Americold, and more, this movement aims to shift the frozen food industry-standard storage temperature from -18°C to -15°C.

These standards have not been updated in over a century and were never based on scientific data, leaving significant room for improvement. Now, the movement for change is gaining momentum.

Why does a mere three-degree change matter? Because energy efficiency at scale is a game-changer. This initiative is grounded in decades of scientific research and operational insights that demonstrate how moving frozen storage setpoints just a few degrees higher can dramatically reduce energy consumption and carbon emissions—without compromising food safety or quality. The result? A smarter, more sustainable cold chain aligned with global climate goals.

At its core, The Move to Minus 15°C is not just news of a technical adjustment—it’s a bold statement about innovation, environmental responsibility, and the power of collective action. And as with all major transitions, success will depend on data, control, and operational intelligence. That’s where Ndustrial comes in.

Move to Minus 15 Safely with Intelligent Temperature Monitoring

As an industry leader in industrial intelligence and energy optimization, Ndustrial is proud to be a key technology partner supporting The Move to Minus 15C. Our mission has always been to help industrial businesses operate more efficiently by making smarter decisions based on real-time data—and this movement is a perfect example of how operational efficiency and sustainability can go hand in hand.

We are already collaborating with several prominent organizations involved in the movement such as GCCA, the Cold Chain Federation, and many others. These partnerships are built on a shared vision of reducing waste, cutting emissions, increasing transparency, and reducing food price inflation.

Ndustrial’s ColdOS® solution suite enables cold chain businesses to improve temperature control while optimizing energy usage. This is especially critical during a temperature transition, where continuous monitoring, risk management, and compliance become even more vital.

The Opportunity: Efficiency, Cost Savings, and Climate Impact

Three degrees of change may sound like a small adjustment, but it carries massive potential for energy savings. Research indicates that even 1°C increase in frozen storage temperatures globally can reduce energy consumption by roughly 2%, totaling over 8 terawatt-hours (TWh)—more than the annual electricity consumption of many countries.

Consider this: if the cold supply chain adopts -15°C as the new standard across even a quarter of its global footprint, the collective reduction in carbon emissions would be equivalent to taking 3.7 million cars off the road.

Additionally, reduced energy consumption directly translates into cost savings for operators. In an industry with tight margins and rising operational costs, the ability to significantly cut utility bills while supporting sustainability targets is a win-win proposition. At a time when food prices are increasingly volatile, these savings are not just welcome—they’re transformative.

Understanding the Risks: Why Robust Temperature Monitoring is Non-Negotiable

Of course, lowering energy usage by increasing storage temperatures is not without its challenges. As temperatures rise, even by a small margin, the margin for error narrows. What used to be a safe buffer is now tighter, meaning every degree—and every minute of downtime—counts more than ever.

Frozen food safety remains paramount, and any deviation from optimal storage conditions can increase risks to product quality and brand reputation. Moving from -18°C to -15°C introduces an acute need for enhanced temperature monitoring and alerts.

As such, the frozen food logistics industry must invest in more sophisticated tools to track, alert, and respond to any fluctuations in temperature.

This is precisely where Ndustrial’s technology excels. Our platform provides continuous, site-wide temperature monitoring, tailored alerts, and integration with a range of IoT sensors and other systems. Whether it’s detecting anomalies or auditing results, Ndustrial helps ensure that temperatures are tracked and minimized.

Solutions That Unlock the Move to Minus 15

One of the most critical enablers of The Move to Minus 15°C is the transition from manual to automated temperature monitoring. Many cold storage facilities still rely on periodic checks or disconnected systems that can’t provide a holistic view of what’s happening moment-to-moment. This is no longer sufficient.

Modern cold storage operations need automated, real-time data collection across multiple points in the facility—something traditional Refrigeration Control Systems (RCS) struggle to offer. While RCS platforms are designed to manage setpoints and refrigerant flow, they often lack the granularity and intelligence to drive decision-making at scale.

That’s why Ndustrial has developed a new layer of intelligence through our newest solution: ColdOS Sense, which provides:

- Continuous, real-time temperature readings throughout the operation

- Easy air temperature heatmap visualizations

- Product-specific temperature estimations

- Smart, duration-based alerts

- Compliance-ready reporting tools for audits and third-party verification

ColdOS Sense allows frozen operations to confidently manage the transition to -15°C, knowing they have the data and insights needed to control risk and drive measurable impact.

The Move to Minus 15°C is more than an operational tweak—it’s a signal that the frozen food supply chain is ready to lead on sustainability. This movement is backed by data, guided by global standards, and supported by a growing network of advocates and technology providers.

Ndustrial: An Expert Solutions Provider in the Cold Supply Chain

Ndustrial is proud to be part of this journey. By equipping organizations with the tools and intelligence they need to make smarter energy decisions, we’re helping pave the way for a more cost-effective and climate-conscious cold chain. Our technology doesn’t just provide data—it delivers actionable insights that allow operators to monitor temperatures and optimize energy usage in real time, reducing carbon emissions while maintaining the high standards of food safety and reliability that the cold chain demands.

With platforms like ColdOS and the Nsight® Energy Intensity Platform, we’re enabling cold chain operations to confidently embrace change, manage risk, and streamline compliance. Together with our partners and the broader industry, Ndustrial is driving forward a new standard—where sustainability and operational excellence go hand-in-hand. The move to -15°C isn’t just a technical shift; it’s a strategic leap toward a better, more energy-intelligent future.

Want to learn more about how Ndustrial can support your journey to -15°C? Contact us today to explore our solutions for real-time energy monitoring and smarter temperature control.